Search results for: 'rega rp8 turntable'

- REGA System OneSpecial Price $1,999.00 Regular Price $2,599.00

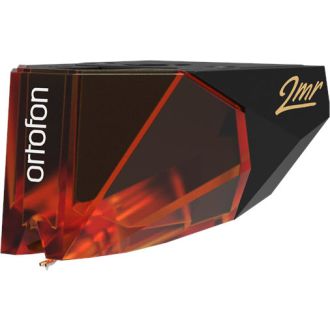

- ORTOFON 2MR Red CartridgeSpecial Price $170.00 Regular Price $189.00

- ORTOFON 2MR Blue CartridgeSpecial Price $325.00 Regular Price $359.00

- ORTOFON 2MR BLACK 250 LVR CARTRIDGESpecial Price $1,485.00 Regular Price $1,649.00

- PRO-JECT E1 Turntable$494.00 Regular Price $549.00